Robotics

New 3D-Printed Materials Sense Their Own Movements

A team of researchers at MIT has developed a new method for 3D printing materials with tunable mechanical properties, which enables them to sense their own movements and interactions with the environment. The team created the sensing structures with one material and a single try on a 3D printer.

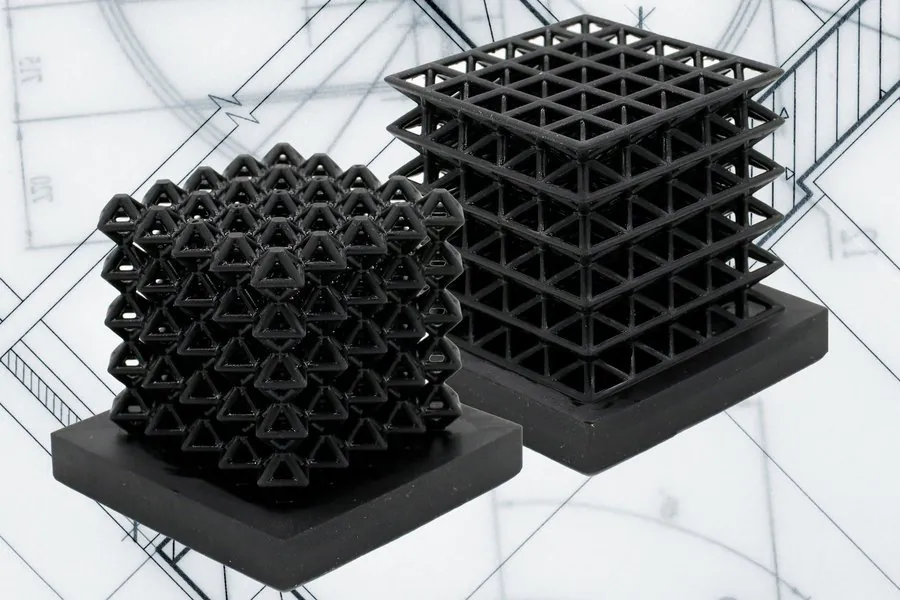

They first took 3D-printed lattice materials and incorporated networks of air-filled channels into the structure during the printing process. They could then extract insight on how the material is moving by measuring the pressure changes within these channels when the structure is squeezed, bent, or stretched.

The lattice materials consist of single cells in a repeating pattern, and by changing the size or shape of the cells, the material’s mechanical properties are altered.

The new technique could eventually help create flexible soft robots with embedded sensors that enable the robots to understand their posture and movements. It could also lead to the development of wearable smart devices that are customizable.

Lillian Chin is co-lead author and a graduate student in the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

“The idea with this work is that we can take any material that can be 3D-printed and have a simple way to route channels throughout it so we can get sensorization with structure. And if you use really complex materials, then you can have motion, perception, and structure all in one,” Chin said.

The paper also includes co-lead author Ryan Truby, a former CSAIL postdoc and current assistant professor at Northwestern University; Annan Zhang, a CSAIL graduate student; and senior author Daniela Rus, the Andrew and Erna Viterbi Professor of Electrical Engineering and Computer Science and director of CSAIL.

The research was published in Science Advances.

3D Printing Technique

The team relied on 3D printing to incorporate air-filled channels directly into the struts that form the lattice. When the structure undergoes movement or is squeezed, the channels deform and the volume of air inside changes. This process enables the researchers to measure the corresponding change in pressure with an off-the-shelf pressure sensor, which provides feedback on how the material is deforming.

“If you stretch out a rubber band, it takes a little time to come back into place. But since we are using air and the deformations are relatively stable, we don’t get these same time-varying properties. The information that comes out of our sensor is a lot cleaner,” Chin says.

The team incorporated channels into the structure using digital light processing 3D printing. The method involves the structure being drawn out of a pool of resin and hardened into a precise shape using projected light. An image is then projected onto the wet resin and areas hit by the light are cured.

As the process moves further along, the sticky resin drips and gets stuck inside the channels, which meant the team had to remove any excess resin before it was cured. They did this by using a mix of pressurized air, vacuum, and intricate cleaning.

“We will have to do more brainstorming from the design side to think about that cleaning process, since it is the main challenge,” Chin continues.

The team used this process to create several lattice structures and demonstrated how the air-filled channels could generate clear feedback when the structures were squeezed or bent.

HSA Soft Robots

The group of researchers also incorporated sensors into handed shearing auxetics (HSAs), which are a new class of materials developed for motorized soft robots. HSAs can be stretched and twisted at the same time, enabling them to act as effective soft robot actuators. However, HSAs are difficult to “sensorize” due to their complex forms.

The team 3D printed one of these HSA soft robots, which was able to carry out various movements like bending and twisting. It was then put through a series of movements for over 18 hours, and the sensor data was used to train a neural network that could accurately predict the robot’s motion.

“Materials scientists have been working hard to optimize architected materials for functionality. This seems like a simple, yet really powerful idea to connect what those researchers have been doing with this realm of perception. As soon as we add sensing, then roboticists like me can come in and use this as an active material, not just a passive one,” Chin says.

“Sensorizing soft robots with continuous skin-like sensors has been an open challenge in the field. This new method provides accurate proprioceptive capabilities for soft robots and opens the door for exploring the world through touch,” Rus continues.

Chin and the team say the future of such technology could lead to things like football helmets tailored to a specific player’s head. These helmets would have sensing capabilities within the internal structure, increasing the accuracy of feedback from on-field collisions.